Earthmoving machines play a crucial role in construction, mining, and infrastructure projects. These machines handle demanding tasks such as lifting, digging, and transporting materials. To perform efficiently, they require reliable components that can withstand intense workloads and challenging conditions.

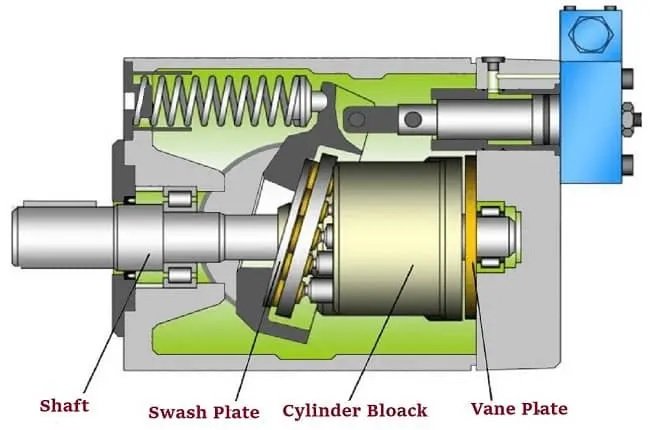

Among the essential components, hydraulic pumps stand out as the driving force behind these powerful machines. They convert mechanical energy into fluid power, ensuring that various attachments and lifting mechanisms operate smoothly. This article will give an overview of how these pumps are essential components for powerful machines.

Consistent Power for Heavy-Duty Applications

Earthmoving equipment relies on a steady flow of energy to perform multiple functions. The ability to generate and control force ensures precision and effectiveness in operations. Machines equipped with high-quality fluid power systems can manage heavy loads, adjust movements accurately, and maintain stability across different terrains.

A well-functioning system not only improves efficiency but also enhances productivity. Operators can complete tasks faster with minimal effort, reducing strain on both machinery and personnel. Dependable equipment suppliers ensure that construction firms have access to durable and high-performance solutions tailored to their needs.

Enhancing Equipment Longevity and Performance

Durability is a key factor in maintaining construction machinery. When systems function efficiently, wear and tear on components is minimised, reducing the need for frequent replacements. Properly maintained systems extend the service life of equipment, saving businesses from costly downtime and repairs.

Using high-quality components also helps prevent overheating and excessive friction, which can damage internal mechanisms. Routine maintenance and sourcing parts from trusted suppliers ensure that machines continue operating at peak performance. Investing in quality solutions leads to long-term operational benefits.

Improved Precision and Control

Handling large machinery requires accurate movement and control. The ability to regulate force and direction ensures safe and efficient operations. A well-designed system allows operators to make precise adjustments, improving overall task execution.

This level of accuracy is particularly important in applications such as trenching, grading, and lifting heavy materials. Reliable systems respond quickly to operator inputs, reducing delays and enhancing workplace safety. Properly maintained equipment ensures that movements remain consistent even under heavy loads.

Reducing Fuel Consumption and Operational Costs

Efficiency is not only about performance but also about cost-effectiveness. A well-maintained system reduces energy wastage, leading to lower fuel consumption. When machinery operates smoothly, it requires less effort to perform tasks, ultimately lowering operational expenses.

Businesses that invest in efficient equipment benefit from reduced maintenance costs and fewer unexpected breakdowns. Reliable suppliers provide components that optimise fuel usage, ensuring that machines run efficiently without unnecessary strain. This approach supports long-term savings and improved resource management.

Maintaining Safety Standards in Heavy Machinery Operations

Safety is a critical factor when operating earthmoving equipment. Machines that rely on efficient fluid power systems ensure smooth and controlled movements, reducing the risk of sudden failures. A well-maintained system allows operators to handle heavy loads with confidence, preventing unnecessary accidents on-site.

Using reliable components enhances overall stability, minimising unexpected shifts or malfunctions. Regular inspections and sourcing equipment from trusted suppliers help maintain safety standards, ensuring that machines function optimally under varying conditions. Prioritising high-performance systems contributes to a safer and more efficient work environment.

Hydraulic pumps are essential for ensuring earthmoving equipment operates efficiently and reliably. These systems provide the necessary power, precision, and durability required for demanding tasks. By choosing high-quality components and working with trusted suppliers, businesses can maximise performance, reduce operational costs, and extend the lifespan of their machinery.